Six Sigma Certification: Unveiling the Hype & Boosting Your Career

Every organization strives for success; otherwise, what’s the point, right? ‘Agile’ and ‘Lean’ aren’t just qualities you’d want in a dancer – they form part of a growing list of methodologies, including Six Sigma, that have been developed in an endeavor to reach and maintain business success. We turn our attention, here, to Six Sigma, which has shown great outcomes in the past when applied correctly. So, what’s all the fuss about?

Brief History of Six Sigma

Bill Smith developed Six Sigma in 1986. A Motorola engineer then aimed to help develop the company’s devices that at the time did not meet the quality requirements. He focused on methods of statistical and quality control taught by Walter Shewhart, Ronald Fisher, and Edwards Deming.

- Walter Shewhart pioneered statistical quality control (SQC) and developed the Plan Do Check Act ( PDCA) model (also called the Shewhart Cycle).

- After World War II, Edwards Deming served in Japan and was instrumental in shaping quality control in Japanese manufacturing. He is credited with developing sampling techniques used by the U.S. Census Department and Labor Statistics Bureau.

- Sir Ronald Aylmer Fisher is considered “the most influential single figure in 20th-century statistics.” His work has popularized many statistical techniques used today. Student’s t-distribution, P-value, F-distribution, among others.

Save Thousands Of Dollars With Coggno Prime Subscription

Why Six Sigma?

Six Sigma is a robust methodology with various frameworks for its implementation, and with multiple concrete benefits; including:

- When correctly employed, it improves business processes by drawing on data gathered from statistical analysis.

- It improves processes by identifying and reducing/eliminating process errors, and monitoring them closely to ensure that they continue to serve their purpose effectively – this ensures sustained quality improvement in an organization.

- The methodology can be applied in virtually any industry but is a favorite in the manufacturing sphere.

- Organizations that have employees who are skilled at identifying process errors and defects are, by extension, in a better position to comply with international and local industry standards.

- Defect reduction minimizes waste, resulting in reduced manufacturing costs and higher income. Failure to create a quality product can be expensive. Creating an under-standard product or service will dramatically reduce costs. That’s the real “quality expense”

- Six Sigma will help streamline processes and reduce customer satisfaction. For example, by applying the Cross-functional Process Mapping (CFPM) technique, Citibank was able to recognize and correct unnecessary steps in their processes, resulting in great customer satisfaction levels.

What is the Six Sigma process?

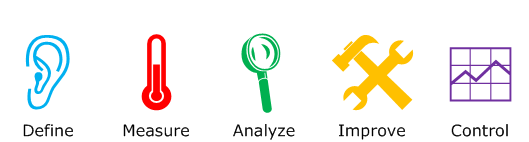

The Six Sigma quality improvement approach comprises five data-driven stages — Defining, Evaluating, Assessing, Enhancing and Control (DMAIC). When fully implemented, DMAIC standardizes an organization’s problem-solving approach and shapes how new process solutions are devised.

1. Define Phase

The “Define” stage aims to classify all relevant details necessary to separate a project, issue or process into concrete, actionable terms. It highlights concrete, grounding process improvements in actual, quantifiable, and qualified information rather than abstract goals.

2. Measure Phase

Organizations determine where current process capacities are in the “Measure” step. Although they recognize that they need to make adjustments and have explicitly listed those adjustments in the Identify process, they can not tweak and customize changes until they have a data-backed baseline.

Introduction To Lean Six Sigma

3. Analyze Phase

Step “Analyze” analyses data obtained during the Measure stage to isolate the exact root causes of process inefficiencies, faults and discrepancies. In short, the data extracts sense. Analyzation perspectives begin to scaffold concrete process changes for the team or company to implement.

4. Improve Phase

The “Improve” initiates formal action plans to address the root problems of your study. Organizations approach what they perceive as root causes of challenges, usually deploying an experiment design strategy to separate multiple variables and co-factors before the true challenge is found.

5. Control Phase

In the final “Control” step, Six Sigma teams build a control plan and deploy your streamlined process. The control plan outlines improved daily workflows, resulting in critical business process variables following accepted quality control variances.

Each of these five phases of the Six Sigma quality improvement model provides a repeatable framework to enhance process capabilities for your company. When fully implemented, organizations can measure the effectiveness and efficiency of critical manufacturing business processes. Results are monitored in a control map, offering quantifiable, comparable process-control data that leverage competitive advantage.

Perfect Solution

Six Sigma is by no means the perfect solution to every problem, and not every person who puts it on their resume will do justice to the methodology. As such, experts advise that practitioners should employ a holistic, context-based approach to Six Sigma and not use it as a one-size-fits-all solution. This is hardly a surprising revelation in a fast-changing work environment.

Although it was developed in the 1980’s, the methodology remains relevant in today’s business world, primarily because Six Sigma’s continuous improvement philosophy aligns with ISO 9001 quality management standards. So, yes, Six Sigma can undoubtedly make a meaningful difference in businesses looking to improve their processes and customer satisfaction.

Maximize Training, Minimize Costs With Coggno Prime

What is the Six Sigma Certification?

Six Sigma quality management is a set of tools and techniques companies use to improve production processes, eliminate defects, and ensure quality. The Six Sigma credential helps verify and eliminate professionals skilled in recognizing threats, errors, or defects in a business method.

Obtaining a Six Sigma Credential typically allows individuals to have some degree of experience and testify to their skill. Certification can help you become a process improvement specialist and enhance your credibility.

Course Recommendations:

If you already have a foundational knowledge of this methodology, or would like to learn how Six Sigma can improve your business processes, Coggno has certification courses aimed at varying levels of comprehension to get you started or to sharpen your skills even further:

• Course 1: Six Sigma Overview

• Course 2: Lean Six Sigma Yellow Belt Certification

• Course 3: Lean Six Sigma DMAIC Project Template

• Course 4: Process Design for Six Sigma

“Quality cannot be copied; there is no step-by-step cookbook that applies equally to all company situations and cultures.”