The last time I watched a fire inspector pause mid-walkthrough, it wasn’t because a pull station was missing or an exit sign was out. It was because the binder looked “complete” until they started asking simple questions. “Show me last month’s extinguisher checks.” “Where’s the documentation for the alarm test?” “Who corrected the issue, and when?” The room got quiet, not from fear of the inspection, but from the realization that the story the building was telling did not match the paper.

That’s what fire safety documentation really is: the story of how your building stays ready on ordinary days, so it can perform on the worst day. When your logs are clean, consistent, and easy to verify, audits go faster, corrective actions get done sooner, and your team stops guessing. A fire extinguisher inspection certification helps tighten that story by setting clear expectations for what gets checked, how it’s recorded, and who is accountable for follow-through. When logs are vague or missing, even a solid safety program can look shaky under scrutiny.

What Auditors And Inspectors Want From Your Records

Auditors and fire officials usually want the same three things: proof the work happened, proof it was done on schedule, and proof issues were corrected. That sounds simple, but many logs fail because they read like a checklist someone rushed through at the end of a shift.

Good records work like a clear timeline. They show the date, the exact device or area, the result, and what changed after a problem was found. A record that says “Checked extinguishers, OK” is rarely enough. A record that says “3rd floor east hallway, ABC-12, pressure in green, pin sealed, access clear, initials, photo attached” is hard to argue with.

fire safety documentation That Holds Up When Someone Asks Follow-Up Questions

Audit-ready documentation is built for follow-up questions, because those questions always come. If a log shows “fail,” an auditor will ask what you did next. If a log shows “pass” every month for two years, they may ask how you know inspections weren’t pencil-whipped. The goal is not perfection. The goal is credibility.

A helpful mindset is to treat every entry like it may need to stand alone six months from now. Could a new safety coordinator read it and understand what happened without calling the person who wrote it? If the answer is no, add a bit more detail and a consistent format. That small effort is what makes records sturdy.

The Recordkeeping Rules That Drive Documentation Quality

Many workplaces improve documentation overnight once they understand the baseline requirements. For portable fire extinguishers, OSHA requires annual maintenance checks and also requires employers to record the annual maintenance date and retain that record for at least one year after the last entry (or for the life of the shell, whichever is less). That record must be available upon request, which means it can’t be buried in someone’s inbox.

If you operate in California, there are also state-level expectations. California regulations include inspection recordkeeping requirements for fire extinguishers and generally expect owners to maintain records of inspected extinguishers, including those needing corrective actions, until the next required maintenance. Local fire code requirements can add another layer, including making records available to the fire code official upon request.

The Core Log Set Most Facilities Need

If you want a practical “starter kit,” focus on the records that map directly to common fire protection systems and routine checks. Keep them grouped by system so an auditor can follow the logic without hunting.

A clean core set often includes:

- Fire extinguisher monthly visual check logs (by location and unit ID)

- Fire extinguisher annual maintenance documentation and service tags

- Fire alarm system inspection, testing, and maintenance reports

- Emergency lighting and exit sign inspection logs

- Fire door and egress checks (where required by your facility type)

- Sprinkler and standpipe inspection/testing records (if present)

- Corrective action log that ties findings to fixes, dates, and owners

This set works best when every system has the same “shape” of documentation: what was checked, what passed, what failed, what you did, and who verified closure.

Fire Extinguisher Logs That Do More Than Check A Box

Extinguisher documentation is one of the easiest areas to strengthen, because the routine is repeatable and the expectations are well known. NFPA guidance describes inspection, testing, and maintenance concepts that many organizations use to structure their programs, including routine inspection and service tracking.

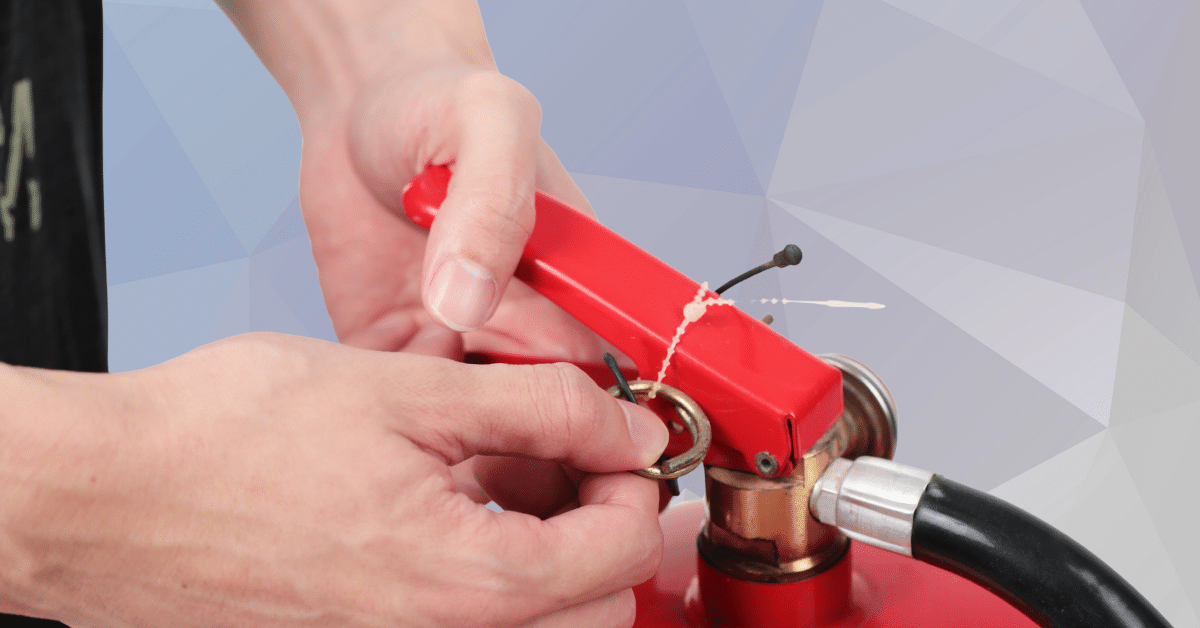

Your monthly log should read like a short field report, not a one-word verdict. A solid entry includes location, extinguisher ID, accessibility, physical condition, pressure indication (if applicable), pin and tamper seal status, and initials. Then it should point to the corrective action log if anything is off.

Here’s the difference in practice: when an extinguisher fails inspection, your documentation should show that it left service, a replacement was placed, and the servicing event is recorded. That way, the “gap time” is visible and managed instead of hidden.

How To spot extinguisher problems Before They Become Findings

Monthly checks are where most issues are caught early, and those issues tend to repeat across industries. The key is training your inspectors to look at the same points every time, then write them down in a consistent way that an auditor can follow. When your team knows how to spot extinguisher problems fast, small issues like blocked access, missing pins, low pressure, or damaged hoses get corrected before they turn into failures, citations, or last-minute scramble fixes.

Common issues your log should capture clearly:

- Blocked access (stored items, furniture, stacked product)

- Missing pin or broken tamper seal

- Damage to hose/nozzle or corrosion on the cylinder

- Low pressure (gauge not in the green) or missing gauge where expected

- Missing or illegible identification and service information

- Wrong type for the hazard area (for example, no Class K near cooking equipment)

In your notes section, write what you saw in plain language, then write what happened next. “Blocked by cartons, cleared at 2:10 pm, photo attached” is stronger than “access issue fixed.” The goal is to make the correction as easy to verify as the problem.

Fire Alarm And Detection Records People Forget Until An Audit

Fire alarm documentation can get messy fast because it involves vendors, testing schedules, device lists, and repairs that happen throughout the year. Many facilities keep the annual report but lose the smaller records that prove ongoing care. That’s risky, because when a device fails or a zone is disabled, auditors often want the trail.

Some guidance documents summarizing NFPA 72 concepts highlight the expectation that records be kept for inspection, testing, and maintenance activities. Even when record retention minimums vary, keeping a clear history helps you defend your program and spot recurring failures.

A strong approach is to keep your fire alarm documentation in three layers: the system inventory (device list and drawings), the scheduled testing reports, and the service/repair history. When those layers align, you can answer the common audit question in seconds: “When did this device last pass, and what happened since?”

The Corrective Action Log That Makes Everything Else Believable

This is the document that turns a pile of inspection forms into a safety system. Without a corrective action log, your records may show problems but not outcomes. Auditors often judge maturity by how you track fixes.

A corrective action log should include: date found, source (which inspection), exact location/device ID, issue description, interim controls, owner assigned, target date, completion date, and verification method. If you want it to hold up, add one more field: “evidence.” That can be a photo, service ticket, invoice number, or vendor report reference.

Two paragraphs of realism: not every issue gets fixed the same day. That’s fine. What matters is that you show control of the timeline. A transparent delay with documented interim protection reads better than a missing record that suggests nobody noticed.

Documentation Habits That Prevent “Pencil-Whipped” Logs

If every monthly inspection is recorded at the same time in the same handwriting, auditors notice. Even if everything is truly fine, the pattern can create doubt. The fix is to add light friction that makes honesty easy.

Use small safeguards that improve trust:

- Rotate inspectors occasionally, with clear training

- Require initials plus printed name or employee ID

- Add a random “verification spot check” by a supervisor

- Attach a photo for a small percentage of monthly checks

- Record time stamps in digital forms when possible

These habits do not add much work, but they make your documentation feel like it came from real observations, not routine paperwork.

Going Digital Without Losing Audit Clarity

Digital logs can be excellent, but only if they are structured for retrieval. If you can’t pull records by device ID, floor, or date range, digital becomes a new kind of mess. The best systems mirror the way inspectors ask questions.

A simple rule: store documentation by system, then by asset, then by date. Keep naming conventions consistent. If you use attachments, tie them to the exact record entry, not a separate folder with vague titles.

Also keep a “quick export” habit. At least quarterly, export a snapshot of key records and store it in a controlled location. If a platform changes, a login breaks, or a vendor relationship ends, you still have your proof.

Training And Accountability Across Compliance Topics

Strong documentation often follows strong management habits. When leaders set expectations, follow through on corrections, and keep recordkeeping simple, compliance improves across subjects. It’s the same reason organizations that run consistent training programs can handle multiple requirements without chaos. The pattern is repeatable: clear responsibility, consistent cadence, and proof that the work happened.

Two paragraphs that matter for culture: documentation isn’t just about audits. It’s how you show your people that safety isn’t a slogan. When employees see that hazards are found, tracked, and fixed, they stop assuming “nothing will change” and start reporting issues earlier.

A 30-Day Plan To Make Your Logs Audit-Ready

If your documentation feels scattered, a focused month can reset it. Don’t try to rebuild everything at once. Build a stable backbone, then expand.

Week-by-week plan:

- Week 1: Inventory assets (extinguishers, alarm panels, devices, emergency lights). Assign IDs where missing.

- Week 2: Standardize forms and naming. Add required fields and a notes section that prompts real observations.

- Week 3: Create or clean up corrective action tracking. Tie every open finding to an owner and a due date.

- Week 4: Run a mock audit. Pull three random records per system and verify you can show “check, result, fix.”

Then keep the momentum with a monthly review: open items, overdue items, and any repeated failures that hint at a bigger problem.

Closing Takeaway And Next Step

Audit-ready records aren’t about fancy templates. They’re about telling the truth clearly, in a way that someone else can verify. When your fire safety documentation is consistent, specific, and tied to corrective action, your facility feels calmer during inspections because you’re not scrambling to reconstruct history.

Pick one system this week, extinguishers are often the fastest win, and tighten the log format, the correction trail, and the retrieval method. Small upgrades, repeated, turn documentation into a safety tool instead of a last-minute scramble.

FAQ

What counts as fire safety documentation during an inspection?

Fire safety documentation usually includes inspection, testing, and maintenance records for systems like extinguishers, alarms, emergency lighting, sprinklers (if present), and egress features. Inspectors often want to see dates, locations or device IDs, results, and proof that problems were corrected. A separate corrective action log helps connect “what we found” to “what we fixed,” which strengthens the credibility of your records.

How long should we keep fire safety documentation?

Retention depends on the system and jurisdiction, but a safe practice is to keep records long enough to show trends and prove follow-through. OSHA requires employers to record annual extinguisher maintenance and retain that record for at least one year after the last entry (or for the life of the shell, whichever is less). Local fire codes may also require records be available to the fire code official on request.

What makes a fire extinguisher log “audit-ready”?

An audit-ready extinguisher log identifies the exact extinguisher, its location, and what was checked, such as access, physical condition, and charge indication. It also documents what happened if something failed: removal from service, replacement, service ticket reference, and completion date. The best logs include brief notes written in plain language so an auditor can understand the finding without guessing what “needs attention” meant.

Can we use digital forms for fire safety documentation?

Yes, digital logs can work very well if they are structured for fast retrieval. Organize records by system, asset, and date, and keep naming conventions consistent. Make sure you can export records quickly for an audit and attach evidence like vendor reports or photos to the exact entry. A digital system should reduce chasing paperwork, not create a new maze of folders.

How do we handle missing or incomplete fire safety documentation from past months?

Start by documenting the gap honestly and rebuilding forward with a stronger process. Do a current inventory of assets, standardize your forms, and restart the inspection cadence with clear ownership. If vendor documentation is missing, request duplicates and store them with your system records. Then use a corrective action log to track any problems found during your reset. Auditors often respond better to a clear recovery plan than to vague backfilled logs.