The first time I realized how fragile “fire readiness” can be, it was during a routine walkthrough with a facilities lead who took real pride in his building. Floors were polished, exit signs glowed, and every cabinet had a label.

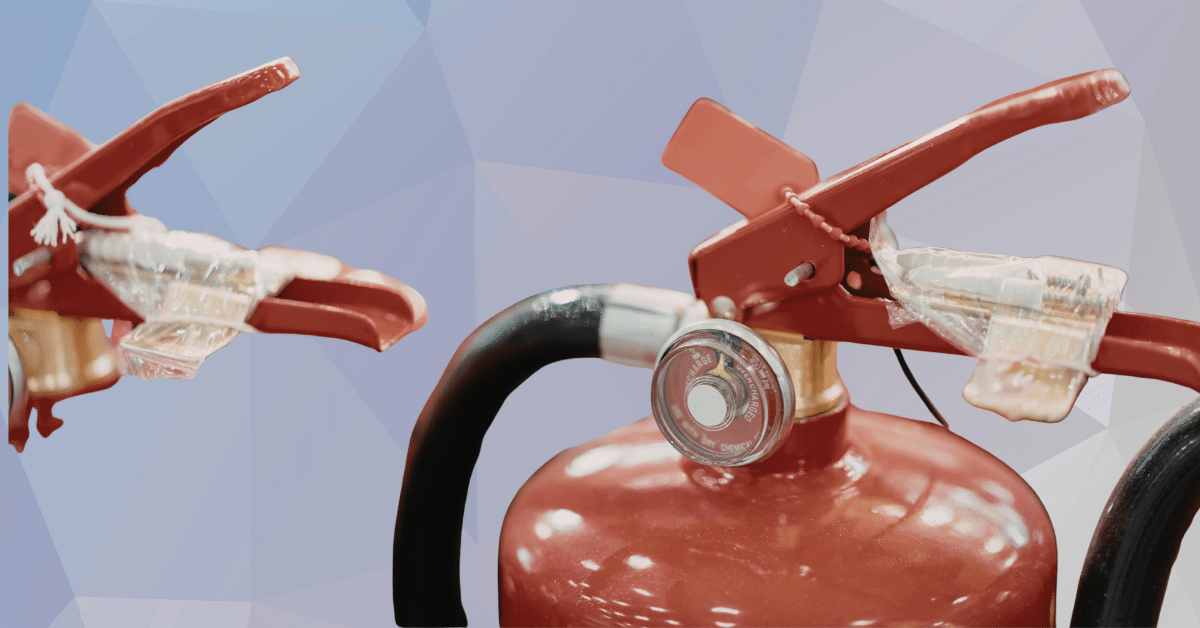

Then he stopped at an extinguisher near the breakroom and frowned. The pressure needle was sitting low, the tag hadn’t been initialed in months, and a stack of delivery boxes had slowly crept into the “grab zone.”

Nothing about it looked dramatic, yet it was the safety equivalent of a seatbelt that might not click when you pull it.

That moment stuck with me because workplace fires rarely announce themselves politely. When something goes wrong, you do not get extra time to “get organized.”

A reliable fire extinguisher maintenance routine is one of those quiet habits that feels boring on a calm Tuesday and feels priceless on the day it matters.

Why Extinguishers Fail When You Need Them Most

Portable extinguishers are simple tools, but they get exposed to the harshest of conditions. They get bumped by carts, soaked by humidity, dusted over during renovations, and hidden behind whatever “temporary” storage becomes permanent.

A gauge can drift out of range, a hose can crack, or a pin can go missing. The extinguisher is still on the wall, so everyone assumes it’s ready.

The risk is not theoretical. NFPA’s national fire-loss reporting for the U.S. shows that non-residential structure fires in 2024 were estimated at 119,500 and led to civilian deaths and injuries. Broader national fire totals also remain high year to year, reinforcing a simple reality: incidents still happen, and early response tools need to work the first time.

Fire Extinguisher Maintenance As A Living Program

Good fire extinguisher maintenance is not a single task you “complete.” It’s a living program with three moving parts: the equipment, the people, and the habits that keep both reliable. If one piece drifts, the whole system weakens.

Start by treating your extinguishers like you treat emergency lighting or first-aid supplies: assigned ownership, a repeatable schedule, and a clear standard for “ready.”

OSHA places responsibility on the employer for the inspection, maintenance, and testing of portable extinguishers in the workplace. That’s a helpful mindset shift, because it turns “someone should check those” into “this is a managed safety system.”

Monthly Visual Checks That Catch Problems Early

A monthly visual inspection is one of the highest-return habits in safety because it’s fast and it catches the small stuff before it becomes a big miss. OSHA calls for monthly visual inspections for portable extinguishers. Think of it like scanning a dashboard before a long drive: you are not rebuilding the engine, you are spotting obvious trouble.

This is where fire extinguisher checks shine as a simple routine that supervisors or trained staff can complete without tools. Keep it consistent, keep it quick, and keep it documented so the habit doesn’t fade when the building gets busy.

- Confirm the extinguisher is in its assigned location and mounted correctly.

- Verify access is clear (no furniture, boxes, or equipment blocking the approach).

- Look at the gauge (if present) and confirm the indicator is in the operable range.

- Check the pin and tamper seal for signs of removal or damage.

- Scan the cylinder, hose, and nozzle for cracks, corrosion, dents, or leaks.

- Verify the label is readable, and the unit matches the area’s hazard type.

After the check, add a short note: pass/fail, date, initials, and any action taken. If something is off, pull it from service right away and replace it with a compliant unit so the area is never left “half protected.”

Placement, Access, And Signage: Make The Tool Reachable

Even a perfectly serviced extinguisher is useless if it’s hard to reach. The goal is simple: someone who is startled, moving fast, and maybe breathing smoke can still spot it and grab it.

That means consistent mounting height, obvious visibility, and a clear path that stays clear even during peak operations.

Treat access like a “no-parking zone.” If you regularly see items drifting into the space, solve it with layout, not lectures. Mark the floor, relocate the extinguisher to a more natural traffic line, or adjust storage habits so the clear zone stays respected.

- Use wall signs or cabinet markers that can be seen over normal clutter.

- Add floor outlines in stockrooms where temporary storage tends to grow legs.

- Place extinguishers near exits and higher-risk areas, aligned with your safety plan.

- Build extinguisher location checks into opening and closing duties for shift teams.

A small visual cue can prevent the slow creep of “stuff” that blocks response time.

Training People To Respond Calmly Under Pressure

A red cylinder on the wall does not automatically create safety. People need confidence, judgment, and permission.

OSHA states that when employers provide portable extinguishers for employee use, they must also provide an educational program covering general principles of extinguisher use and the hazards of incipient-stage firefighting.

This is where a well-designed fire extinguisher inspection course can support your program beyond basic awareness.

The best training connects the “what” to the exact work happening onsite: what fuels exist, which extinguisher types are present, where the evacuation routes are, and when the right move is to leave and let emergency response handle it.

- Teach simple decision rules: small and contained fire, clear exit behind you, correct extinguisher type, and a clear call for help.

- Practice the PASS method (Pull, Aim, Squeeze, Sweep) with calm coaching and realistic pacing.

- Train staff to report missing tags, blocked access, or low-pressure gauges as normal safety actions.

- Reinforce that evacuation and alarm activation come before “hero moments.”

Training should feel like rehearsing a routine, not memorizing trivia. The goal is steady hands and good judgment, not bravado.

Turning Maintenance Into A Culture, Not A Calendar Reminder

A strong Fire Extinguisher Maintenance program feels like good housekeeping: visible, repeatable, and owned. The most effective workplaces make it part of how they operate, not a once-a-year scramble before an inspection.

They talk about it briefly in safety huddles, they keep access clear as a shared expectation, and they reward reporting problems early.

If you want one practical next step, do a short walkthrough this week with fresh eyes. Pick five extinguishers across different areas, check access, check tags, check gauges, and talk to one employee in each area: “If something small caught fire here, what would you do first?”

The answers will tell you where the real gaps are, and you can tighten the system before you ever need it.