The first time I saw someone grab the wrong extinguisher, it wasn’t in a dramatic movie moment. It was a real workplace, a small breakroom, and a toaster oven that started smoking. The person did the right thing by reacting fast, but they reached for whatever was closest without checking the label. A supervisor stopped them in time, and the situation stayed small. Afterward, the room got quiet, because everyone realized something uncomfortable: most people recognize an extinguisher, but far fewer people know which one they’re actually supposed to use.

That gap matters. Fire extinguishers are like tools in a toolbox. A screwdriver is great, unless the job needs a wrench. The wrong extinguisher can make a fire worse, waste precious seconds, or put someone in danger. A fire extinguisher inspection certification supports smarter choices by ensuring labels are legible, units are correctly placed, and employees are trained to recognize extinguisher types before an emergency forces a split-second decision. This guide breaks down the most common extinguisher types, what they’re meant for, and how to make smart choices under pressure.

Why Fire Extinguisher Type Matters More Than People Think

Fires don’t all behave the same. A paper fire burns differently than a grease fire. An electrical fire carries shock risk. A flammable liquid fire can spread across a surface fast, like a slick that suddenly wakes up. Extinguishers are built for specific fuel types, which is why the letters and symbols on the label are more than decoration.

Another reason type matters is confidence. Employees are more likely to act when they trust what’s in their hands. When people feel unsure, they hesitate, and hesitation is when small fires grow legs. The goal is not to turn everyone into a firefighter. The goal is simple: help employees match extinguisher type to the kind of fire they might actually see at work.

Fire Classes In Plain English

Before comparing ABC, CO2, and K, it helps to know what the fire “classes” mean. Think of classes as the fire’s food source. Cut off the right food source and the fire loses energy.

Here’s the quick breakdown:

- Class A: ordinary combustibles like paper, wood, cardboard, cloth

- Class B: flammable liquids like gasoline, solvents, oils, some paints

- Class C: energized electrical equipment like panels, cords, appliances

- Class K: cooking oils and fats, mostly in commercial kitchens

You’ll sometimes see Class D for combustible metals in specialized settings. If your workplace handles metal powders or reactive metals, you need targeted training and equipment.

Fire Extinguisher Types Explained For Everyday Workplaces

When people ask for a “quick guide,” they usually want a simple answer: Which extinguisher should we buy and where should we put it? The honest answer depends on your risks, but most workplaces rely on three common types because they cover the most typical scenarios.

ABC extinguishers are the all-around option for many general areas. CO2 extinguishers are common near electrical equipment and places where residue would be a problem. Class K extinguishers are designed for commercial cooking spaces where grease fires behave in their own stubborn way. Understanding how each works will make the labels feel obvious, not confusing.

ABC Extinguishers: The Workhorse You See Most Often

ABC extinguishers are usually the most familiar because they show up in offices, warehouses, retail spaces, and mixed-use facilities. They are designed to handle Class A, B, and C fires, which covers a lot of real-world workplace risk.

ABC units are typically dry chemical. They work by interrupting the chemical reaction of the fire and smothering the fuel surface. That’s why they can knock down flames quickly, but they also leave a powdery residue that can be messy and damaging to electronics.

ABC is a strong choice for common areas like hallways, storage rooms, and general workspaces. It’s also the extinguisher people tend to grab in panic, so it’s worth pairing ABC placement with clear signage and quick training.

Where ABC Makes Sense And Where It Doesn’t

ABC works well where you might face multiple fire sources. It’s the “multi-tool” of extinguishers, especially in buildings with mixed materials, packaging, and equipment.

Use ABC in areas like:

- Offices with paper, furniture, and breakroom appliances

- Warehouses with cardboard, pallets, and shipping supplies

- Retail spaces with mixed combustibles and electrical fixtures

- Maintenance rooms that store small amounts of flammable liquids

ABC is not the best fit in every scenario. In spaces with sensitive electronics, server rooms, or equipment that cannot tolerate residue, ABC can create costly cleanup and downtime. In kitchens with deep fryers, ABC can knock down some flames, but it is not designed for the specific behavior of hot cooking oils.

CO2 Extinguishers: Cleaner For Equipment, Different For People

CO2 extinguishers are popular near electrical equipment because they leave no residue. They work by displacing oxygen around the fire and cooling the area. That “clean discharge” is the big advantage, especially in server rooms, electrical closets, labs, and areas with expensive machinery.

There’s a practical warning with CO2 that training should stress. CO2 is a gas, and it reduces oxygen. In a tight space, careless use can create breathing risk for the person operating it. It also comes out extremely cold and can cause frostbite if someone grabs the horn or nozzle incorrectly.

CO2 is a great tool when the fire is small and the environment calls for a clean approach. It’s not a magic fix for every situation, and it’s not meant for fires deep in Class A materials like smoldering stacks of paper.

Common CO2 Use Cases And Mistakes To Avoid

CO2 can be the right choice when you want to stop a small fire without coating the room in powder. It also helps reduce secondary damage.

Good CO2 placements include:

- Electrical rooms and panel areas

- Server rooms and IT spaces

- Laboratories with sensitive equipment

- Manufacturing stations with electrical controls

Mistakes that show up often include using CO2 outdoors in windy conditions where the gas disperses too quickly, or trying to fight a deep Class A fire where material continues to smolder. CO2 can knock down visible flame, but if the fuel stays hot, the fire can flare right back up once oxygen returns.

Class K Extinguishers: Built For Grease Fires That Fight Back

Class K extinguishers are designed for commercial kitchen fires involving cooking oils and fats. These fires behave differently than typical flammable liquid fires because cooking oils reach very high temperatures and can re-ignite quickly. Tossing water on a grease fire can cause violent splatter that spreads the fire, which is why kitchens require special planning.

Class K extinguishers typically use a wet chemical agent that cools the oil and creates a soapy layer that smothers the surface. That chemical reaction helps stop re-ignition, which is one of the biggest challenges with fryer and range-top fires.

If your facility has a kitchen, cafeteria, food truck, or any operation with commercial cooking equipment, Class K is not optional. It is the correct tool for the most likely kitchen scenario.

Kitchen Scenarios Where Class K Matters Most

Kitchen fires are often fast and stressful, and they tend to happen during peak activity. That’s why placement and training are just as important as the extinguisher itself.

Class K is designed for situations like:

- Deep fryers and grease-heavy cooking lines

- Grill stations with accumulated grease

- Range tops where oil ignites during cooking

- Kitchen areas near hood suppression systems

Even in a kitchen, the response should start with quick judgment. If the fire is beyond the early stage, if it’s spreading, or if smoke is heavy, the right move is to activate alarms, evacuate, and call emergency services according to your workplace plan.

Reading The Label Without Overthinking It

Labels can look busy, but the key information is usually simple: the class ratings, the operating instructions, and the inspection tag. Many modern extinguishers show icons, which help employees decide faster.

Teach employees to look for:

- The letters: A, B, C, or K

- The symbols: trash can and wood pile for A, gas can for B, plug for C, frying pan for K

- Basic steps for operation

- Inspection and service history on the tag

The label is also where you’ll find the capacity rating. Two extinguishers can both be “ABC” and still have very different knockdown ability.

Placement And Access: Small Details That Decide Outcomes

An extinguisher that’s blocked by boxes is basically a wall decoration. The best extinguisher is the one someone can reach in ten seconds without stepping toward the fire. Placement is about real behavior, not ideal diagrams.

A good placement plan accounts for how people move through the space. Put extinguishers near exits and along normal paths, not tucked into corners behind equipment. In kitchens, place Class K units near cooking areas but not so close that someone has to reach over a fire to grab one.

It also helps to keep signage consistent and visible. When smoke shows up, the room can feel unfamiliar. Clear signs reduce hesitation.

Maintenance, Inspections, And Fire Safety Documentation

Extinguishers need ongoing care. Pressure drops, pins go missing, hoses crack, and units get moved without anyone realizing. Regular checks keep the tool ready, but they also protect the business in a compliance situation.

That’s where fire safety documentation matters. Inspection logs, service records, and training proof help confirm that extinguishers were present, maintained, and ready for use. In many workplaces, these records are the difference between “we thought we were covered” and “we can show what we did.”

Documentation also helps internally. It identifies problem areas, like a unit that keeps getting blocked, or a location where inspections are repeatedly missed.

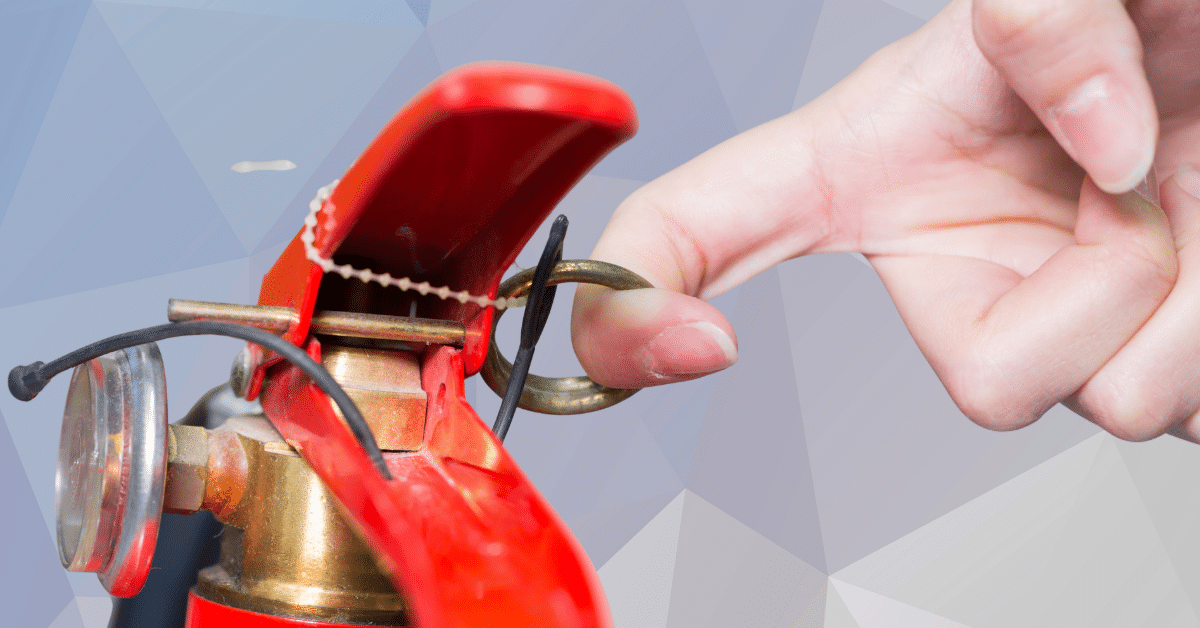

Training Employees To Use Extinguishers Without Taking Unnecessary Risks

Extinguisher training should build confidence while also setting clear boundaries. People should know the goal is to handle early-stage fires only, and that personal safety comes first.

A simple approach many workplaces use is a quick checklist:

- Keep your back toward a clear exit

- Use the correct extinguisher type for the fire class

- Aim at the base of the flames, not the smoke

- Stop if smoke thickens, the fire spreads, or you feel unsafe

- Report the incident and replace or recharge the extinguisher afterward

Training is also a good time to explain what happens after discharge. Even if the fire goes out, the area may still be hot, smoky, or contaminated. Post-incident steps matter.

Building A Respectful Reporting Culture Alongside Safety Training

Workplace safety improves when people speak up early. That includes reporting blocked extinguishers, missing inspection tags, or confusion about which extinguisher to use. It also includes reporting interpersonal issues that make people hesitant to raise concerns.

Some organizations pair safety programs with other compliance training, because respectful workplaces tend to have stronger reporting habits. When employees trust they won’t be mocked, blamed, or retaliated against, they are more likely to flag hazards and near-misses before they become incidents.

The connection is simple: safer environments are built on clear expectations and mutual respect, both in physical hazards and in how people treat each other.

Quick Comparison: ABC Vs CO2 Vs K

If you want a fast mental shortcut, focus on what each type is best at and what each type struggles with. The goal isn’t memorization. It’s recognition.

- ABC: broad coverage for ordinary combustibles, flammable liquids, and electrical fires; leaves residue

- CO2: clean discharge, strong for electrical and small flammable liquid fires; less effective for deep Class A; breathing risk in tight spaces

- Class K: designed for cooking oil and grease fires; best for commercial kitchens; not meant to replace kitchen suppression systems

After reading this, most employees can walk up to an extinguisher and quickly decide whether it fits the environment they’re in.

Conclusion: Match The Tool To The Fire Before You Need It

Fire extinguishers should not be mystery objects on the wall. When employees know what ABC, CO2, and Class K extinguishers are designed to do, they’re less likely to hesitate and less likely to grab the wrong tool in a stressful moment.

A smart next step is a quick walk-through of your facility. Identify which extinguisher types you have, where they are placed, and which hazards exist in each area. Then reinforce the habits that make response safer: keep access clear, keep inspections consistent, and keep training practical. That preparation turns an extinguisher from a symbol into something people can actually rely on.

FAQ

What Does “Fire Extinguisher Types Explained” Mean In Simple Terms?

It means understanding which extinguisher matches which kind of fire. Different fuels burn differently, and extinguishers use different agents to stop that burning. ABC covers common combustibles, flammable liquids, and electrical fires. CO2 is often used around electrical equipment because it leaves no residue. Class K is designed for commercial cooking oil fires that can re-ignite. Knowing the type helps employees act faster and safer.

Is An ABC Extinguisher Safe To Use On An Electrical Fire?

Yes, as long as it’s rated for Class C, which most ABC units are. ABC extinguishers are commonly used around energized equipment because the dry chemical agent does not conduct electricity the way water can. The tradeoff is residue. If you discharge ABC on electrical equipment, you may prevent a bigger loss, but you can also create cleanup and damage concerns. When clean discharge matters, CO2 is often preferred.

Why Would A Workplace Choose CO2 Over ABC?

CO2 is often chosen in areas where residue would be a problem, like server rooms, electrical closets, labs, or equipment stations. It puts out fire by displacing oxygen and cooling the area, and it leaves no powder behind. The downside is it’s not as effective on deep Class A fires like smoldering paper or cloth. It also requires training because CO2 can reduce breathable air in tight spaces.

Do I Need A Class K Extinguisher If There Is A Small Kitchen At Work?

If the kitchen uses commercial cooking equipment, deep fryers, or regularly handles large amounts of cooking oil, Class K is the correct type. Cooking oil fires can re-ignite and behave aggressively, and water can spread the fire through splatter. For a basic breakroom microwave and coffee setup, Class K is usually unnecessary. The deciding factor is whether cooking oils and fats are heated in a way that creates grease-fire risk.

How Can Employees Remember Which Extinguisher To Use During Stress?

The best method is not memorizing every detail. It’s practicing recognition. Teach employees to look at the label letters and icons and to connect them to the fire’s fuel source. Many workplaces also do quick walk-through drills so people know what’s mounted in their area. Pair that with a simple rule: if the fire is growing, smoke is heavy, or you feel unsafe, evacuate and follow the emergency plan.