A Day In The Life Of A Busy Safety Manager

You probably remember a day like this. The phones are ringing, a supervisor needs help with a near miss, and the plant manager wants an update on your safety metrics. In the middle of it all, someone appears at your door holding a jug of cleaner and asks, “Can I mix this with the solvent we use in the shop?”

You glance at the label, your brain juggling symbols, signal words, and hazard statements while the clock keeps ticking. You think about the new hires who started last week, the veteran who does things “the old way,” and the contractor who never got a proper briefing.

Moments like that are where GHS HazCom Training for Employees really lives, not in binders or slide decks, but in quick decisions on busy days.

When employees know how to read a label, locate the correct Safety Data Sheet, and choose the appropriate protection without guessing, those stressful conversations turn into calm, confident ones.

Why GHS HazCom Training For Employees Matters To Real People

Behind every container of chemicals, there is a human story. The custodian who takes pride in leaving the floors spotless. The technician who mixes solutions by memory because “that’s how we’ve always done it.” The line worker who is embarrassed to admit they do not fully understand the pictograms.

Without clear HazCom training, people fill in the gaps with habits, rumors, or trial and error. That is when headaches, rashes, breathing problems, and corroded tools start to appear.

Over time, trust in the safety program weakens. Workers start to think, “If no one has time to explain what is in this stuff, how much does my health really matter here?”

When training is practical, respectful, and consistent, the story changes. People recognize that chemical safety is not just a set of rules for regulators. It is a promise that everyone goes home with the same lungs, skin, and eyesight they brought to work that morning.

Making GHS And HazCom Feel Less Like Jargon

GHS can sound like alphabet soup: classifications, categories, hazard statements, precautionary phrases. OSHA’s Hazard Communication Standard adds another layer. For a busy employee, it can feel like learning a new language on top of an already demanding job.

Your goal is not to turn everyone into a chemist. Your goal is to give them a simple map:

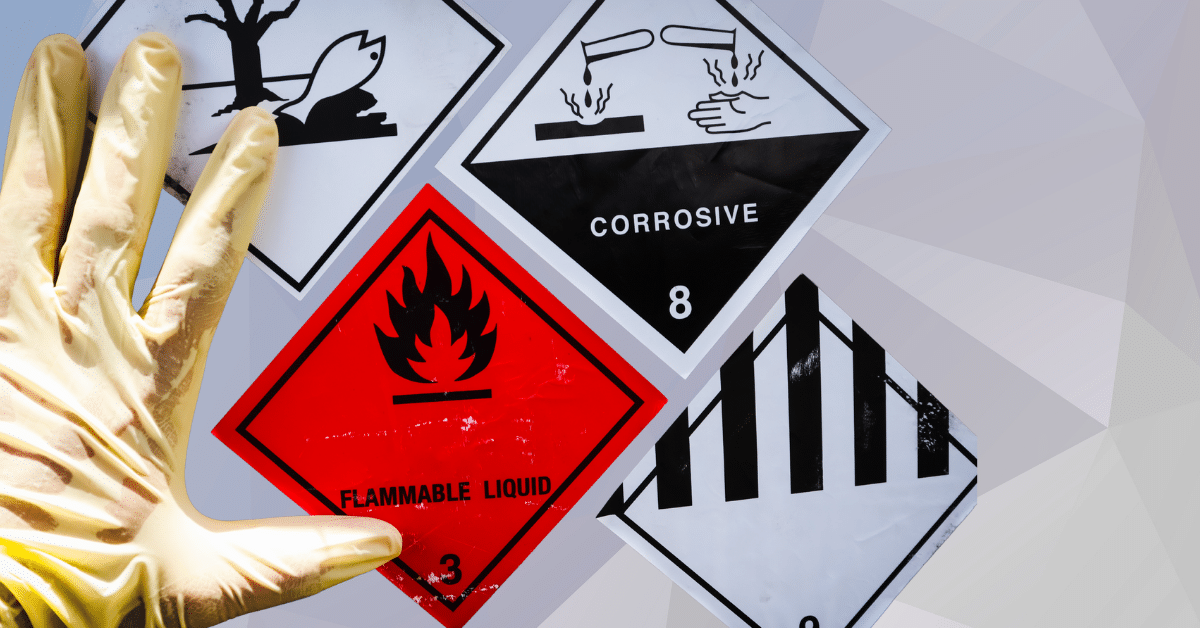

- Labels tell you how this product can hurt you and how to work with it safely

- Pictograms give quick visual cues, even from across the room

- Safety Data Sheets hold the details when you need them

- The written HazCom program describes how your workplace handles and stores those products

Courses such as a GHS Hazard Communication Basics course can help people connect the dots. When employees see how these pieces fit together in their work areas, the jargon fades, and real understanding takes its place.

From Checklists To Conversations

Many organizations started with HazCom training as a checklist item. Everyone sat in a room once a year, clicked through slides, signed the sheet, and went back to work. The paperwork looked perfect, yet people still mixed chemicals in mop buckets or poured liquids into unlabeled spray bottles.

A stronger approach feels less like a lecture and more like a conversation. You might:

- Bring real containers from the floor into the training room

- Ask teams to point out which labels seem confusing

- Invite people to share stories about near misses or “close calls.”

- Walk together to the SDS station and practice finding key sections

When training looks and feels like real life, employees stop seeing it as something extra. It becomes part of how they talk to each other about work, right alongside production targets and quality checks.

Turning Online Courses Into Real-World Habits

Online training offers a practical way to reach busy teams on different shifts. An engaging GHS HazCom course can cover the basics, show realistic scenarios, and document completion for audits.

On its own, though, an online module can feel distant from the noise, smells, and pressures of the actual work area. The magic happens when you pair it with everyday practice:

- After the course, have supervisors ask one simple label question during pre-shift meetings

- Use toolbox talks to review a single pictogram at a time

- During safety walks, ask employees where they would find the SDS for a nearby product

- Invite feedback on what still feels unclear or intimidating

This small, steady rhythm reinforces the course content until careful behavior becomes second nature.

Common HazCom Gaps You Can Fix Quickly

Most safety leaders can point to at least one of these headaches:

- Secondary bottles or spray containers with no labels

- SDS binders that do not match what is actually on shelves

- Temporary workers who never received a proper chemical safety briefing

- Old labels that stayed on containers long after formulations changed

- Employees who think PPE is “overkill” for specific tasks

GHS HazCom training provides a natural reason to clean up these items. When people encounter confusing labels or missing information, invite them to speak up.

Celebrate reports of small issues, then fix them fast. That response demonstrates that speaking up makes the workplace safer for the whole team.

Building A HazCom Plan Around Real Roles

A one-size approach rarely fits an entire workforce. Think about the mix of people who handle chemicals at your site:

- New hires who may never have worked around hazardous materials

- Long-time employees with strong habits, both good and bad

- Maintenance staff who see “one-off” tasks with unusual products

- Office staff who only touch chemicals when they grab a bottle of cleaner

Each of these groups needs different examples and practice. New employees benefit from clear, simple stories and lots of time with labels. Experienced staff may need a respectful reset, especially if products have changed.

Maintenance teams need extra time on non-routine tasks, while office staff need a quick, practical overview that fits their reality.

When people feel that training was built with their job in mind, they pay closer attention and ask better questions.

What A Strong Safety Culture Looks Like Around Chemicals

You can often feel the health of a safety culture just by walking the floor. In a workplace with strong HazCom habits, you might notice:

- Labels that are clean, readable, and consistent

- SDS information posted where people actually look for it

- Employees putting on eyewear and gloves without being reminded

- Supervisors correcting small issues calmly and quickly

- Workers stopping to ask questions before trying something new

No program is perfect. Spills happen, labels peel, and someone always forgets a step. The difference is how people respond. In a strong safety culture, teams treat every close call as a chance to learn, not a reason to blame.

GHS HazCom training provides a shared language for discussing what went wrong and how to prevent a recurrence.

Leadership’s Role In Keeping HazCom Alive

Employees take their cues from what leaders talk about and where they spend time. When managers ask about chemical safety on plant tours or during staff meetings, the topic gains real weight.

Simple habits from leadership can make a big difference:

- Asking “What does that pictogram mean for you?” during a walk-through

- Joining a HazCom training session instead of just signing off on it

- Thanking employees who spot labeling problems or storage concerns

- Allocating time and budget for updates to training, labels, and SDS systems

When workers see that leaders are curious, present, and willing to learn alongside them, they are far more likely to speak up and stay engaged.

Choosing Training Resources That Respect Your People

Not all training is created equal. The best HazCom resources:

- Use plain language instead of dense technical terms

- Show real-world photos and scenarios that resemble your workplace

- Offer flexibility for different learning styles and literacy levels

- Make it easy for you to track participation and follow up with extra coaching

Whether you run sessions in person, online, or both, the heart of the program is respect. When people feel respected, they are much more willing to ask, “I am not sure what this symbol means, can you walk me through it?” That question alone can prevent injuries and build trust.

Keeping The Forklift Driver Safe Next Time

Think back to the worker standing in your doorway with a jug of cleaner. Imagine the same scene six months from now, after your teams have completed updated GHS HazCom training and had regular safety talks.

Instead of asking “Can I mix this?” that employee might say, “I checked the label and the SDS. It looks like these two products react badly, so I grabbed the right one from the approved list.”

That small shift is what this work is really about. Not perfect paperwork, not fancy graphics, but quiet moments where people use what they learned to protect themselves and their coworkers. Step by step, those moments add up to a workplace where chemical safety feels normal, expected, and shared by everyone.